Vertically divided cards.

- The address side of the card must be divided into a right portion and a left portion, with or without a vertical rule. The left portion is the message area.

- The delivery address, postage, and any USPS marking or endorsement must appear in the right portion. The right portion must be at least 2-1/8 inches wide (measured from the right edge of the card, top to bottom inclusive).

- For cards claimed at the Presorted price, nondelivery address information may extend into the right portion only above the address block and if the information is shaded or surrounded by a border that has at least 1/8 inch clearance between the delivery address block and the border. Mailers may choose not to shade or border the nondelivery address information if there is at least 1/8 inch of clear space around the delivery address block.

- For cards claimed at the automation price, the standards for automation-compatible mail in3.0 , and 202.5.0 , must be met.

- The address side of the card must be divided into an upper portion and a lower portion, with or without a horizontal rule. The portion of the address side that does not contain the delivery address is the message area.

- The delivery address, postage, and any USPS marking or endorsement must appear within the portion containing the delivery address. As an alternative, when the delivery address appears within the lower portion, it is permissible for the postage, return address, and any USPS marking or endorsement to appear in the upper portion. The portion bearing the delivery address must be at least 1-1/2 inches high (measured from the top or bottom edge of the card, as applicable, right edge to left edge inclusive).

- For cards claimed at the Presorted price, nondelivery address information may extend into the portion containing the delivery address only if it appears above the address block and if the information is shaded or surrounded by a border that has at least 1/8 inch clearance between the delivery address block and the border. Mailers may choose not to shade or border the nondelivery address information if there is at least 1/8 inch of clear space around the delivery address block.

- For cards claimed at the automation price, the standards for automation-compatible mail in3.0 , and 202.5.0 , must be met.

1.2.8 Tearing Guides

1.2.9 Double Cards

- The reply half of a double card must be used for reply only and may not be used to convey a message to the original addressee or to send statements of account. The reply half may be formatted for response purposes (e.g., contain blocks for completion by the addressee).

- A double card must be folded before mailing and prepared so that the address on the reply half is on the inside when the double card is originally mailed. The address side of the reply half may be prepared as business reply mail, courtesy reply mail, meter reply mail, or as a USPS Returns service label.

- Plain stickers, seals, or a single wire stitch (staple) may be used to fasten the open edge at the top or bottom once the card is folded if affixed so that the inner surfaces of the cards can be readily examined. Fasteners must be affixed according to the applicable preparation requirements for the price claimed. Any sealing on the left and right sides of the cards, no matter the sealing process used, is not permitted.

- The first half of a double card must be detached when the reply half is mailed for return.

1.2.10 Enclosures in Double Cards

2.0 Physical Standards for Nonmachinable Letters

2.1 Criteria for Nonmachinable Letters

2.1.1 Letter-size Mailpieces

A letter-size piece is nonmachinable if it has an exterior surface that is not made of paper or for pieces more than 4-1/4 inches high or 6 inches long does not meet the minimum thickness of 0.009 under 1.1.1a or if it does not meet the standards in 3.0 . A mailpiece is nonmailable if it does not meet the minimum dimensional standards in 1.1.1 . Windows in envelopes made of paper do not make mailpieces nonmachinable. Attachments do not render mailpieces nonmachinable if allowed by eligibility standards according to the class of mail and if not prohibited in 3.0 . In addition, a letter-size piece is nonmachinable if it weighs more than 3.5 ounces.

2.1.2 Postcard-size Mailpieces

A postcard-priced mailpiece is designated a nonmachinable letter subject to nonmachinable letter prices as follows:

- Postcards not meeting the standard of a minimum of 0.009-inch thickness under1.2.1a .

- Postcards not meeting the aspect-ratio requirement under1.2.1e .

2.2 Additional Criteria for First-Class Mail Nonmachinable Letters

2.3 Additional Criteria for USPS Marketing Mail Nonmachinable Letters

The nonmachinable prices in 243.1.0 apply to USPS Marketing Mail letter-size pieces that have one or more of the nonmachinable characteristics in 2.1 . Mailers must prepare all nonmachinable letters as described in 245.5.0 .

2.4 Additional Criteria for Periodicals Nonmachinable Letters

The Outside-County nonbarcoded and In-County nonautomation letter prices in 207 also apply to Periodicals letter-size pieces that have one or more of the nonmachinable characteristics in 2.1 .

2.5 Priority Mail Express and Priority Mail Letters

3.0 Physical Standards for Machinable and Automation Letters and Cards

3.1 Basic Standards for Automation Letters and Cards

Letters and cards claimed at any machinable, automation, or USPS Marketing Mail carrier route price, must meet the standards in 3.0 . Unless prepared as a folded self-mailer, booklet, or postcard under 3.14 through 3.17 , each machinable or automation letter must be a sealed envelope (the preferred method) or unenveloped. If unenveloped, each letter must be sealed or glued completely along all four sides or prepared under 3.15 .

3.2 Paper Weight

Mailpieces should be constructed from high tear strength paper stock. All references in 3.0 to paper basis weight are for book-grade paper (500 25-inch by 38-inch sheets) unless otherwise stated. Except as required under 3.0 , envelopes, or letter-size mailpieces sealed along all four sides, must be made of paper with a minimum 50 pounds paper basis weight or equivalent. The conversion table in Exhibit 3.2 provides a paper basis weight cross-reference.

3.3 Dimensions and Shape

Each machinable or automation letter-sized piece must meet the dimensional standards in 1.1.1 . Automation priced letter-sized mailpieces are not subject to 1.1.1c (rectangular) when they are prepared as a trailing edge die-cut (TED-C) automation piece under the “Trail Edge Die-Cut (TED-C) Process for Eligibility at Automation Letter Prices” advisory on PostalPro at postalpro.usps.com.

3.4 Standards for Letter-Size Pieces Containing One Disc (CD or DVD)

3.4.1 Basic Standards for One Disc in a Letter-Size Mailpiece

A letter-size mailpiece containing one disc and meeting the general standards in 3.0 and the specific standards in 3.4.3 is considered automation-compatible. A mailpiece with one enclosed disc not meeting these standards must be tested and approved for automation-compatibility. For this purpose, mailers must submit 5 sample mailpieces and a written request to the local postmaster or business mail entry manager for submission to the Pricing and Classification Service Center (PCSC).

3.4.2 Disc Size and Placement

- 120 mm (4.7 inches) in diameter.

- 2 mm (0.08 inch) in thickness.

3.4.3 Dimensions and Other Physical Standards for Automation-Compatible Enveloped Letters Containing Discs

- Height, not more than 6 inches or less than 5.5 inches high.

- Length, not more than 9.75 inches or less than 7.25 inches long.

- Thickness, not more than 0.25 inch or less than 0.009 inch thick.

- Weight, not more than 3 ounces.

- A piece up to 8 inches long must be made of paper with a minimum 70-pound paper basis weight or equivalent.

- A piece over 8 inches long (up to 9.75 inches long) must be made of paper with a minimum 80-pound paper basis weight or equivalent.

- Discs in mailpieces made of the minimum basis weight paper must be inserted into a protective sleeve.

- Not be a window envelope, unless tested and approved under3.4.1 .

3.4.4 Dimensions and Shape Standards for Automation-Compatible Unenveloped Disc Carriers

- Height, not more than 6 inches or less than 5.5 inches high.

- Length, not more than 9.75 inches or less than 7.25 inches long.

- Thickness, not more than 0.25 inch or less than 0.009 inch thick.

- Weight, not more than 3 ounces.

- Be prepared from paper stock meeting the industry standard with a minimum 75-pound paper basis weight or equivalent, with none less than 71.25 pounds. The stock must be free from groundwood unless coated with a substance adding to the stock‘s ability to resist an applied bending force.

- Any folds or perforations in the mailpiece must be parallel to the address.

- Must meet the tabbing requirements for pieces prepared with folds or perforations parallel to the address provided in3.14 .

3.4.5 Unacceptable Characteristics for Automation-Compatible Letter-Size Pieces with Discs

3.5 Maximum Weight, Machinable and Automation Letters and Cards

- Booklets, folded self-mailers, and unenveloped disc carriers - 3 ounces.

- Machinable enveloped letters and cards - 3.5 ounces. (see3.6 for pieces over 3 ounces.)

- Automation enveloped letters and cards - 3.5 ounces (see3.6 for pieces over 3 ounces.)

3.6 Heavy Letter Mail (over 3 ounces)

3.7 Aspect Ratio

3.8 Wraps and Closures

3.9 Staples and Saddle Stitching

3.10 Rigid and Odd-Shaped Items

Rigid items (e.g., pens, pencils, keys, bottle caps) are prohibited within mailpieces. Reasonably flexible items (e.g., credit cards) are permitted. Subject to 3.12 , odd-shaped items (e.g., coins and tokens) are permitted if firmly affixed to and wrapped within the contents of the mailpiece and envelope to streamline the shape of the mailpiece for automated processing.

3.11 Tabs, Tape, and Glue

- Translucent paper tabs should be made of paper with a minimum of 40-pound paper basis weight.

- Opaque paper tabs should be made of paper with a minimum of 60-pound paper basis weight with a tear strength of at least 56 grams of force in the machine direction (MD) and 60 grams of force in the cross direction (CD).

- When a barcode clear zone is required under202.5.1 , tabs in the barcode clear zone must have a paper face meeting the standards for background reflectance and, if the barcode is not preprinted by the mailer, the standards for acceptance of water-based ink.

- Vinyl tabs and cellophane tape closures are not acceptable within the barcode clear zone.

- Tabs must be tight against the edge of the mailpiece. A maximum 1/16-inch overhang is recommended.

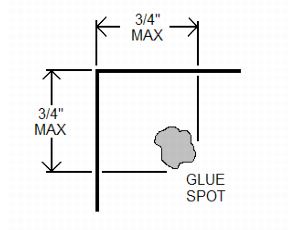

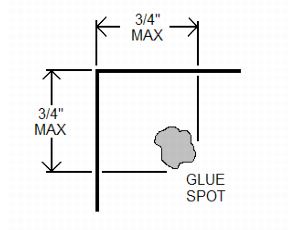

- Glue spots may be used in lieu of tabs (as indicated inExhibit 3.16.5 through Exhibit 3.16.8 ) and must be placed within 3/4 inch of the open edges (see Exhibit 3.11f ).

Exhibit 3.11f Glue Spot Placement

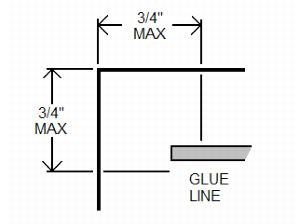

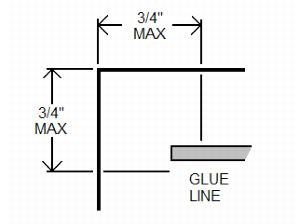

- Continuous glue lines may be used as cover-to-cover seals for specific designs. When using glue as a sealing method, it must be placed along the entire length of the open edge and end no more than 3/4-inch from the open ends (seeExhibit 3.11g ) unless standards require use of a continuous 1/8-inch wide glue line under 3.11h . For folded self mailers see 3.13.4b .

Exhibit 3.11g Glue Line Placement

- Continuous, 1/8-inch wide, glue lines must be placed along the entire length of the open edge and end within 1/4-inch of the open ends. The selvage along the open edge must not exceed 1/4 inch. Glue lines created with a permanent adhesive that is not tacky when dry are preferred.

- Die-cut flaps, those with irregular shapes, must be well sealed to the non-address side panel using tabs, glue spots or elongated glue lines; however, a 1/8 inch continuous glue line that follows and seals the contour of the shape is highly recommended.

3.12 Flexibility Standards for Automation Letters

3.12.1 Machinability

3.12.2 USPS Services for Flexibility Testing

3.13 Labels, Stickers, Release Cards, and Perforated Pockets Affixed to the Outside of Letter-Size Mailpieces

3.13.1 Use

A label, sticker, perforated pocket (under 3.13.6 and 3.13.7 ), or release card may be placed on a letter-sized mailpiece that is eligible for automation letter prices, including barcoded carrier route letters meeting automation standards. Release cards and perforated pockets may not be affixed to pieces mailed at First-Class Mail card prices; see 1.2 for other restrictions on attachments to cards. A USPS Marketing Mail or Periodicals letter with a label, sticker, release card or perforated pocket must meet additional standards in 243.2.5 These attachments may be:

- A label or sticker less than 0.007 inch thick, and a perforated pocket other than repositionable notes affixed under202.7.0 , as follows:

- A permanent label or sticker, or perforated pockets under3.13.7d2 (designed not to be removed or relocated), affixed directly to the outside of the mailpiece with permanent adhesive.

- A relocatable label, to be placed on the outside of, or on the contents of, a reply mailpiece. Labels must be affixed under3.13.2 or 3.13.3 .

3.13.2 Pressure-Sensitive Label

3.13.3 “Sandwich” Label

3.13.4 Letter-Size Piece with Attached Release Card

- Be between 8 and 9-1/2 inches long (inclusive). With one release card affixed, be between 4 and 6 inches high (inclusive); with two release cards affixed, be between 5-1/2 and 6 inches high (inclusive).

- No address element, including any address block barcode, may be closer than 1 inch to the right edge of the mailpiece.

- The surface smoothness of all letter-size pieces must be at least 190 Sheffield Units.

- Enveloped letters must be made of paper with a minimum 60-pound paper basis weight or equivalent, and have a maximum thickness of 1/8 (0.125) inch. Window envelopes must have only one closed panel address window, no larger than 1-1/2 x 4-1/4 inches.

- Card-type letters, not mailed at card prices, have a maximum thickness of 0.025 inch as mailed.

- All letter-size pieces other than enveloped letters and card-type pieces (such as folded self-mailers and booklets) must have a maximum thickness of 0.10 inch as mailed. Mailpieces with two affixed release cards must meet the following additional conditions:

- Pieces requiring tabs must be sealed with 1-1/2 inch nonperforated tabs, unless larger tabs are required by standards for the specific mailpiece design.

- Booklets must have a minimum cover weight of 70-pound paper basis weight or equivalent.

- Folded self-mailers must have a minimum cover weight of 100-pound paper basis weight or equivalent.

3.13.5 Standards for Release Cards

- Be rectangular, but allowed with finished corners having a radius of at least 1/8 inch up to 1/2 inch.

- Be between 2 and 2-1/2 inches (inclusive) high, and between 3 and 3-1/2 inches (inclusive) long. Affix each card with either edge parallel to the length of the mailpiece. Affix two cards on the same side of the mailpiece under these conditions:

- Stack cards vertically, one above the other, on the same side (address side or nonaddress side), or

- Affix the cards side-by-side across the mailpiece length on the nonaddress side only.

- When affixing cards one above the other on the address side, maintain a space of at least 1/2 inch from the leading edge, the trailing edge and the top edge.

- When affixing cards one above the other on the nonaddress side, the right edge of the cards must be placed between 5 and 6 inches from the leading edge of the mailpiece, but no closer than 1/2 inch from the trailing edge. Maintain a space of at least 1/2 inch from the top edge.

- When affixing cards side by side on the nonaddress side, the right edge of the leftmost card must be placed at least 5 inches from the leading edge of the mailpiece, and the rightmost card must be placed at least 1/2 inch from the trailing edge of the mailpiece. Maintain a space of at least 1/2 inch from the top edge.

- Adhesive used to affix the backing to the mailpiece must have a peel adhesion of at least 2 pounds/inch to stainless steel with a 20 minute dwell time, at 300"/minute at 90 degrees per ASTM test D3330F.

- Adhesive used to attach the release card to the backing must have a peel adhesion of at least 1.5 ounces/inch to stainless steel with a 30 minute conditioning time, at 300"/minute at 90 degrees per ASTM test D3330F.

3.13.6 Letter-Size Pieces with Perforated Pockets

Perforated pockets are permanent attachments to letter-sized mailpieces that may be opened to reveal a small printed insert. Advertising may be printed on the components used to create a perforated pocket and on the printed insert within. Perforated pockets may not be used to conceal or contain matter bearing personal information except as provided in 243.2.2 . Perforated pockets may be used on letter-size USPS Marketing Mail and Periodicals and are not considered sealed against Postal inspection. When affixed to Periodicals mail, advertising printed on the perforated pocket and any inserted matter is counted as part of the total advertising content of the host publication. Pockets may be used in lieu of labels to bear a permit imprint indicia showing that postage is paid if indicia information does not appear on the perforated panel or on the perforations used to create the perforated panel. A maximum of two perforated pockets are permitted on eligible letter-size mailpieces that have the following characteristics:

- Be between 8 inches and 9-1/2 inches long (inclusive).

- Be between 4 inches and 5-1/2 inches high (inclusive).

- Mailpieces must be prepared with a minimum paper basis weight or equivalent as follows:

- Envelopes - 60 pound

- Booklets - 70 pound

- Folded Self-Mailers - 100 pound

- Oversized card-type letters paid at letter prices must be at least .012 in thickness.

3.13.7 Standards for Perforated Pockets

- The perimeter of the pocket is affixed with permanent glue with a minimum adhesive strength of 2 lbs/inch to stainless steel with 20 minute dwell time at 300" minute at 90 degrees per ASTM Test D3330F.

- The attached material has a minimum tear strength of 100gf (MD) and (CD) per TAPPI T414.

- The cut/tie ratio for perforation is 1:1 with a minimum tie size of 1 mm. One double cut may be made at the lower trailing edge corner of the perforated panel of the pocket.

- The pocket is:

- Between 1-1/2 inches and 2-3/4 inches in both height and length.

- Has an affixed area no more than 0.012 inch thick and a perforated panel no more than 0.03 inch thick. Perforated pockets may not exceed the thickness of the host mailpiece. They may not cause the host to have an uneven surface and must not interfere with readability of the address, barcode, or postage information.

- At least 1 inch from the bottom and leading edge.

- At least 1/2 inch from the top and trailing edge.

- At least 1 inch from the bottom edge.

- At least 1/2 inch from the top.

- At least 5 inches from the left edge but no closer than 1/2 inch from the right edge.

- Stack perforated pockets vertically, one above than the other. Do not affix the pockets side by side across the mailpiece length.

- A space up to 1/2 inch is allowed between pockets.

3.14 Folded Self-Mailers

3.14.1 Definition

3.14.2 Physical Characteristics

- Height: A minimum of 3-1/2 inches and a maximum of 6 inches.

- Length: A minimum of 5 inches and a maximum of 10-1/2 inches.

- Thickness: A minimum of 0.007 inch; (0.009 inch if the height exceeds 4-1/4 inches or if the length exceeds 6 inches); the maximum thickness is 1/4 inch.

- Maximum Weight: 3 ounces.

- Rectangular, with four square corners and parallel opposite sides.

- Aspect ratio: within 1.3 to 2.5 (see3.7 ).

- Maximum number of panels: 12, except under3.14.2h .

- Quarter-folded self-mailers made of a minimum 70-pound paper basis weight or equivalent may have as few as 4 panels. Quarter-folded self-mailers made of 55 pound or greater newsprint must have at least 8 panels and may contain up to 24 panels.

3.14.3 Panels

- External panels created by folding must be equal or nearly equal in size.

- The final folded panel creates the back (non-address) side of the mailpiece. The open edge of the back panel must be at the top or within 1inch of the top or trailing edge of the mailpiece. For horizontal folded tri-fold or multi-fold pieces, the addressed panel may be the final folded panel if the leading edge is sealed according to3.14.4a .

- The final folded edge must be the bottom of a folded self-mailer unless prepared as an oblong. The final folded edge of an oblong folded self-mailer must be the leading (right) edge.

- Internal shorter panels must be covered by a full-size panel, and count toward the maximum number of panels. Optionally, internal shorter panels may be secured but must have only one edge that is shorter and be no further than one inch away from the edge of the external panel.

- Folding methods and the subsequent number of panels created when folding a single sheet of paper are:

- Bi-fold: folded once forming two panels.

- Tri-fold: folded twice forming three panels.

- Oblong: paper folded once to form two rectangular panels with one elongated dimension and parallel opposite sides. The final folded edge is on the leading (shorter) edge.

- Quarter-fold: folded twice with each fold at a right angle (perpendicular) to the preceding fold. One sheet of paper quarter-folded creates four panels.

- The folded edge of a flap must be flush with the top edge of the mailpiece and end one inch or more above the bottom edge, except under3.14.3f4 . Flaps must be at least 1-1/2 inches when measured from the top of the mailpiece.

- Flaps must be secured by a sealing method in3.14.4 .

- Flaps with die-cut shapes must be firmly secured with tabs, glue line, glue spots or elongated glue lines. A 1/8 inch wide continuous glue line that seals the contour of the die-cut is strongly recommended.

- Flaps on oblong pieces must be at least 5 inches long at the longest point when measured from the leading edge and must end more than one inch from the trailing edge.

3.14.4 General Sealing Methods

- Tabs must meet the standards for tabs in3.11 . The size and number of tabs required is determined by the weight of the mailpiece and optional design elements as follows:

- To seal folded self-mailers that weigh up to 3 ounces created in bi-fold, tri-fold formats, pieces with multiple interior folds and a final fold on the bottom, and quarter-fold mailpieces that weigh up to one ounce; place two nonperforated tabs on the top edge, one within 1 inch from the leading edge and another within 1 inch from the trailing edge, or place one tab on the leading and another on the trailing edge, both placed within 1 inch from the top. Additionally, horizontal folded tri-fold and multi-fold pieces having the final folded panel as the addressed panel must include an additional 1-inch tab (1-1/2 inch preferred) for pieces weighing up to 1 ounce; or a 1-1/2 inch tab for pieces weighing over 1 ounce, placed 1/2 inch from the bottom of the leading edge. Instead of a tab, a 3/8-inch glue spot or 1/8-inch wide glue line placed 1/2 inch from the bottom and no more than 1/4 inch from the leading edge may be used. The glue spots or lines must be adhered from the addressed panel to the internal panel when the fold is completed.

- To seal quarter-fold mailpieces made with newsprint that weigh more than 1 ounce up to 3 ounces, affix two tabs, one on the leading edge and one on the trailing edge within 1 inch from the top, and affix a third tab on the lower leading edge 1/2 inch from the bottom (see3.14.5b ).

- To seal oblong pieces that weigh up to 3 ounces, affix one tab in the center of the top edge and one tab in the center of the trailing edge (preferred) or affix both tabs on the trailing edge within 1 inch of the top and bottom edges. Tabs may not be placed on the bottom of an oblong piece.

- Continuous glue lines at least 1/8 inch wide (0.125 inches).

- Three or four glue spots at least 3/8 inch (0.375 inch) in diameter.

- Three or four elongated glue lines. Seal folded self-mailers that weigh up to 1 ounce with lines at least 1/2 inch long. Seal folded self-mailers that weigh more than 1 ounce with elongated glue lines that are each at least 1 inch long and 1/8 inch wide, or with glue lines that are each at least 1/2 inch long and 1/4 inch wide.

- Distribute glue spots and elongated glue lines evenly along the sealed edge(s).

- Quarter-fold self-mailers must be sealed with tabs.

3.14.5 Paper Weight and Sealing Requirements

All references in 3.0 to paper basis weight are for book-grade paper unless otherwise stated (see 3.2 ). Interior optional elements such as attachments or enclosures are not subject to the host piece‘s book-grade paper basis weight standards. When multiple optional design elements are incorporated in one mailpiece, the standards for the design element with the highest paper weight and corresponding sealing methods apply. Folded self-mailer paper weights and sealing methods are:

- Folded self-mailers, (except quarter-fold mailpieces) as described in3.14.3e1 through 3.14.3e3 :

- Up to 1 ounce: 70-pound paper basis weight or equivalent sealed with a continuous glue line, three glue spots; or elongated glue lines under3.14.4b ; or two 1-inch tabs under 3.14.4a1 and 3.14.4a3 .

- Over 1 ounce: 80-pound paper basis weight or equivalent sealed with a continuous glue line, four glue spots; or four elongated glue lines under3.14.4b or two 1-1/2 inch tabs under 3.14.4a1 and 3.14.4a3 .

- Up to 1 ounce: 70-pound paper basis weight or equivalent sealed with two 1-inch tabs.

- Over 1 ounce: 80-pound paper basis weight or equivalent sealed with two 1-1/2-inch tabs.

- Newsprint: 55 pound minimum paper required. Seal pieces one ounce or less with two 1-1/2-inch tabs and those weighing over one ounce with three 1-1/2-inch tabs, see3.14.4a2 .

- Up to 1 ounce: 100-pound paper basis weight or equivalent sealed with glue under3.14.4b or two 1-1/2-inch tabs under 3.14.4a1 and 3.14.4a2 .

- Over 1 ounce: 120-pound paper basis weight or equivalent sealed with glue under3.14.4b or two 2-inch tabs under 3.14.4a1 and 3.14.4a2 or three 1-1/2-inch tabs under 3.14.4a1 .

- Up to 1 ounce: 80-pound paper basis weight or equivalent sealed with glue under3.14.4b or two 1- 1/2-inch tabs under 3.14.4a1 and 3.14.4a2 .

- Over 1 ounce: 100-pound paper basis weight or equivalent sealed with glue under3.14.4b or two 2-inch tabs under 3.14.4a1 and 3.14.4a2 or three 1-1/2-inch tabs under 3.14.4a1 .

3.14.6 Die-Cut Elements

- Die-cut address windows (used to convey address information) must meet standards for window envelopes under601.6.3 and meet the following additional conditions:

- The maximum window size is 4 inches long by 2 inches high.

- When an address window appears on a mailpiece, no other die-cut openings may be made on the exterior panels.

- Limited to two on only one external panel and must be positioned at least 1-1/2 inches apart .

- Either circular with a 2-inch maximum diameter or rectangular with a maximum of 2 inches long by 1-1/2 inches high with slightly rounded 1/4 inch radius corners.

- Placed at least 1-1/2 inches from all edges of the mailpiece if on the addressed side.

- Placed at least 5 inches from the leading edge and 1-1/2 inches from all other edges if on the non-addressed side.

3.14.7 Perforated Pull-Open Strips and Pop-Out Panes

- Two parallel perforated lines must be spaced at least 1/2 inch apart creating a pull open strip. Position perforated strips parallel to the height of the mailpiece at least 5 inches from the leading edge and 2 inches from the trailing edge. Position perforated strips parallel to the length of the mailpiece at least 1 inch from the top. Perforations have a 1mm cut (max)/1mm tie (min) ratio.

- Pop-out panes with perforations around the outer edges have a maximum size of 4 inches long by 4 inches high. The following conditions apply:

- Place panes at least 1 inch from any edge.

- Use 1mm cut (max)/1mm tie (min) ratio.

- When using two panes, space them at least 1 inch apart.

- Address elements may not appear in perforated openings.

- The outer edges of the pull-open panel are a maximum of 4 inches long by 4 inches high.

- If prepared with multiple panes, they must be spaced at least 1 inch apart.

- Panes must be placed at least 1 inch from all edges.

- Perforation patterns have 1 mm cut (max)/1 mm tie (min) ratio.

3.14.8 Loose Enclosures

- Must be contained securely within the mailpiece.

- Must be inserted in an interior pocket or secured by any method that prevents excessive shift during normal handling. Pockets are not counted as panels.

- Folded self-mailers with die-cut openings may contain enclosures only if the inserted material is larger than the die-cut opening.

- Enclosed material does not exceed the maximum thickness of:

- 0.05 inch thick for mailpiece weights up to 1 ounce.

- 0.09 inch thick for mailpiece weights over 1 ounce.

3.14.9 Attachments

Attachments must be secured on the outside of a folded self-mailer under 3.13 . Attachments must be secured within a folded self-mailer under the following conditions:

- The attachment is affixed to an inside panel and secured to it at least 1/2 inch from any edge.

- The attached material may not exceed a maximum thickness of:

- 0.05 inch thick for mailpieces weighing up to 1 ounce.

- 0.09 inch thick for mailpieces weighing over 1 ounce.

3.14.10 Addressing

3.15 Other Unenveloped Mailpieces

3.15.1 Open-Sleeve Style Letter-Size Mailpieces

- Join panels using 1/8 (0.125) inch continuous glue lines.

- If flaps are used, they must be a minimum of at least 1-1/2 inches wide created as inner flaps adhered at the leading and trailing edges to the panel from which the flap is formed.

- All paper basis weight requirements in3.14.5d must be met.

- Matter prepared within open-sleeve style mailpieces must meet the standards in3.14.8 or 3.14.9b through 3.14.9f .

3.15.2 Letter-Size Mailpieces with Tear-Off Strips

- Be constructed of a minimum of 60-pound paper basis weight or equivalent.

- Tear-off strips may be up to 9/16 inch (0.5625) wide.

- Tear lines (single lines of perforations) on pieces that weigh 1 ounce or less; recommended minimum cut/tie pattern of 1mm cut (max)/1mm tie (min) ratio or equivalent.

- Tear lines (single lines of perforations) on pieces that weigh more than 1 ounce; minimum cut/tie pattern of 1mm cut /2mm tie (min) ratio or equivalent.